Model DX : Sizes 0.75 - 3.0 Tons

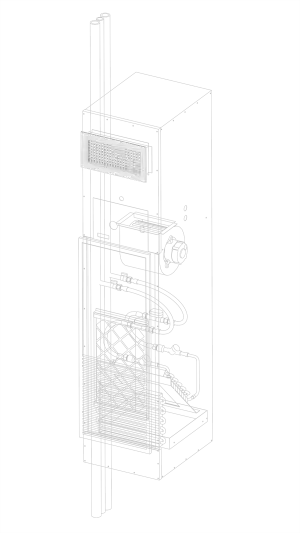

The Unilux HVAC DX Hybrid fan coil unit is an innovative HVAC system that provides year-round heating and cooling with less in-suite noise and reduced building energy costs than traditional 4-pipe systems. For heating, a building-wide hot water system circulates through the coil, functioning similarly to a conventional fan coil system. Cooling is achieved through an eco-friendly refrigerant-charged evaporated-cooling coil, paired with an external condensing unit typically located on a suite balcony, effectively reducing in-suite noise.

Equipping your fan coil with our patented integrated Energy Recovery Ventilation (ERV) technology introduces fresh air into the suite while minimizing energy loss through an advanced heat transfer core. This not only enhances the efficiency of heating and cooling but also facilitates the transfer of moisture between the exhaust and fresh air for heightened resident comfort.

Unilux HVAC vertical stack fan coil units meet the requirements of UL 1995 / CSA22.2 #236 – Issue 2011 Standard for safety heating and cooling equipment.

DX Hybrid

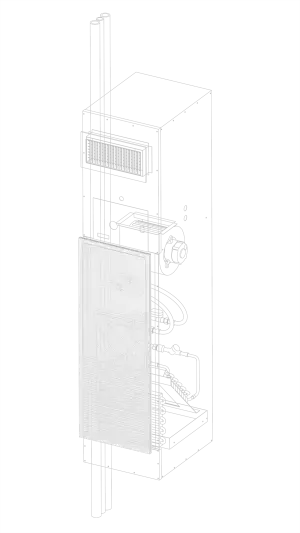

Manufactured with 20-gauge satin steel. Configured with front, back, left, right or top supply air openings. Cabinet is fully insulated with 1″ fibreglass with a thermosetting resin. It is coated on the air stream side with an acrylic facing without the use of flammable adhesives. Insulation inside the unit has a flame-spread rating no more than 25 and a smoke-developed rating no more than 50.

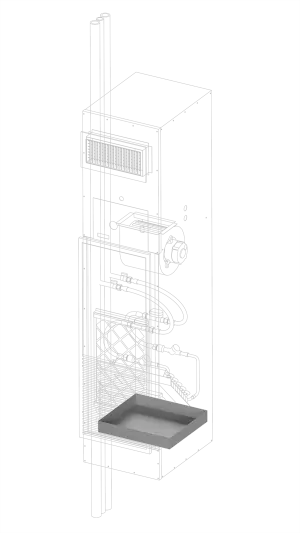

Drain pan is a single stamped stainless steel product designed to slope to allow for complete drainage. The drain hose from the outlet to the condensate riser forms a running P-trap. The underside of the drain pan is insulated with ½” thick thermal and sound insulation.

The overflow sensor detects rising drain pan levels and turns off the unit to prevent leaking. Anti-Freeze Temperature Sensor activates hot water connections when return air is below +4°C (40°F) to prevent freezing.

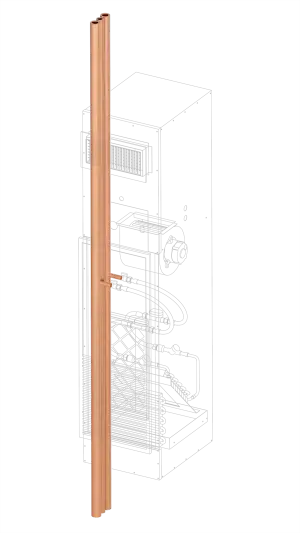

Supply and return risers are type ‘L’ copper and condensate risers are type ‘DWV’. All have 75mm (3″) deep expanded ends to facilitate field installation. Supply and return risers are insulated with 1″ fibreglass covered with a vapour barrier jacket, which complies with ASTM 84 for flame-spread and smoke-developed ratings. The insulation is continuous over the riser length within the height of the cabinet.

Double deflection supply grilles and registers have adjustable vertical or horizontal louvers. Registers are constructed with light-gauge metal complete with adjustable opposed blade dampers.

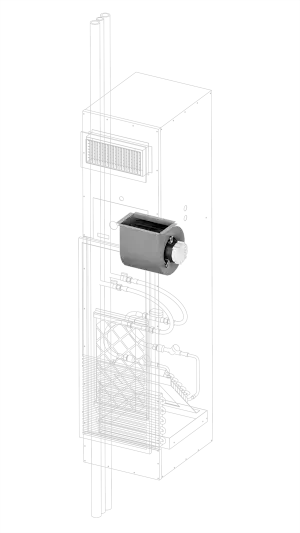

A thermally-protected, multi-speed ECM motor is resiliently mounted to a centrifugal fan which has a galvanized steel forward-curved DWDI wheel in a galvanized housing.

Available CFM: 350, 450, 600, 800, 1000, 1200.

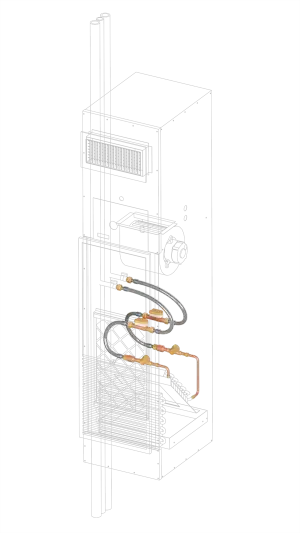

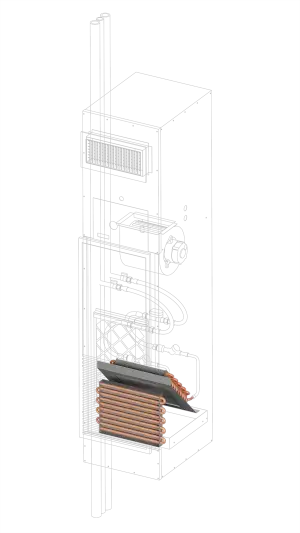

Coils are corrugated aluminum fins mechanically bonded to ½” OD Copper tube. The number of rows and circuiting are selected to suit scheduled capacities. Coils are tested at 450 psig and are rated for a maximum working pressure of 300 psig.

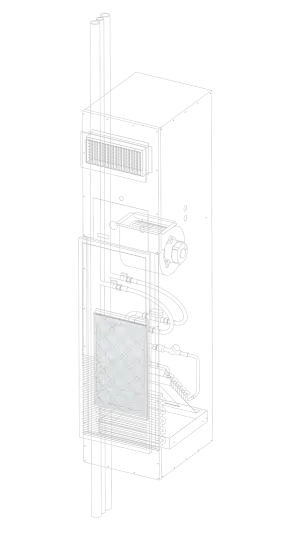

MERV 8-13 filters available.

20-gauge steel construction finished in a durable enamel powder coat. Includes a hinged door for easy filter exchange.

A standard factory assembled 2-way control valve with motorized electrical “on/off” controlling is provided. 3-way motorized valves on top and bottom of each riser allow for continuous flow through riser system. Maximum entering water temperature each control valve is 200°F, and maximum operating pressure is 300 psig.

Constructed with ½” type “L” copper, and stainless steel braided flex hoses to allow for movement due to expansion and contraction of risers; include shut-off ball valves with flare nuts in the supply and return branches for easy removal.